I have corrected my air leak issues and am using a good separator and filter now so I believe I have eliminated air supply issues. Still to no avail I cannot get good cuts around the tabbed area.

But I was still having issues so I went as far as to completely delete the path rules. When I am in sheetcam the path is entirely green. At this point I need some more guidance so any and all recommendations are welcome. I have a Hypertherm Powermax 85 I could wire in if someone thinks that would make a difference. I used path rules to slow it down and saw some improvement, but what I can’t seem to figure out is why my inside corners on the small squares got so sharp at 60% of the feed rate, but the inside corners on the outer perimeter at 60% and 50% of the feed rate is so lousy.Īm I screwing up in my path rules? Is something to do with my consumables (even though I have used new ones)? Is it my plasma cutter? One the sides with the tabs, where the cutter is jogging in X and Y a lot in relatively short distances, my corners are rounded or not even fully cut. I attached photos of the part I have repetitively cut with various changes to settings/code. My top side of the cut is narrower than the bottom now.

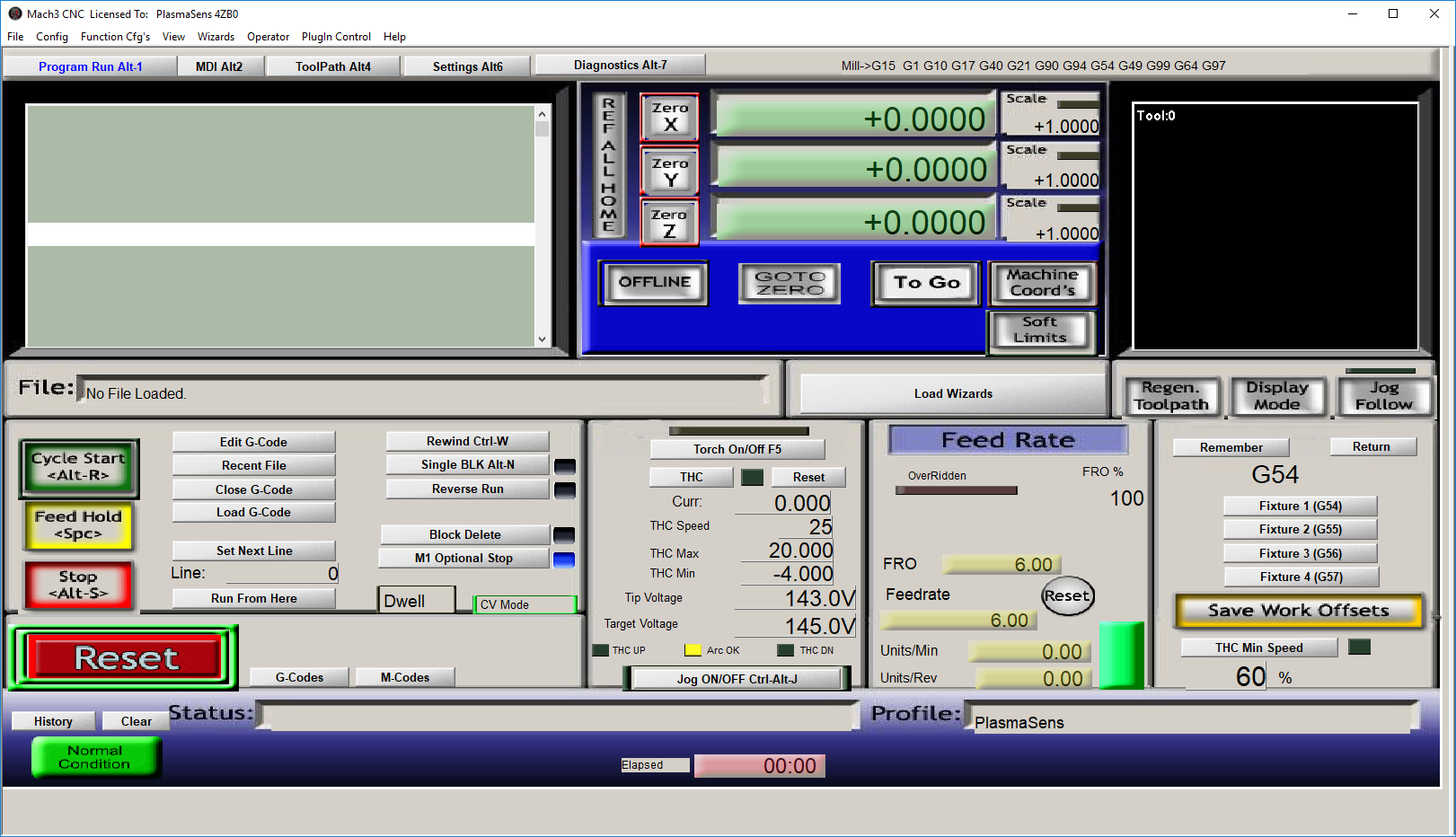

I have a Primeweld Cut 60 that I have been using and I never calibrated the air flow to start, since doing that my bevel has reduced and actually reversed direction. I should note, I am very new to sheetcam, especially using path rules. My corners on outer perimeters are a wreck. I have tried to make adjustments to reduce bevel and improve my corners through some plasma cutter settings and path rules in sheetcam and while I have seen some improvements I am still not there. I eliminated the table as the source for the bevel, because the bevel is always on the same edge of the part no matter how I orientate it. I am having issues with bevel and corners. I am currently using SheetCam for camming and I am cutting with a Primeweld Cut 60. So I have a Langmuir Systems Crossfire Pro.

0 kommentar(er)

0 kommentar(er)